GPU temperature90.5ºc

Reach out and let's chat!

Fill the form

Leave your details to receive the PDF case study

Fill the form

Cooled by

Corintis

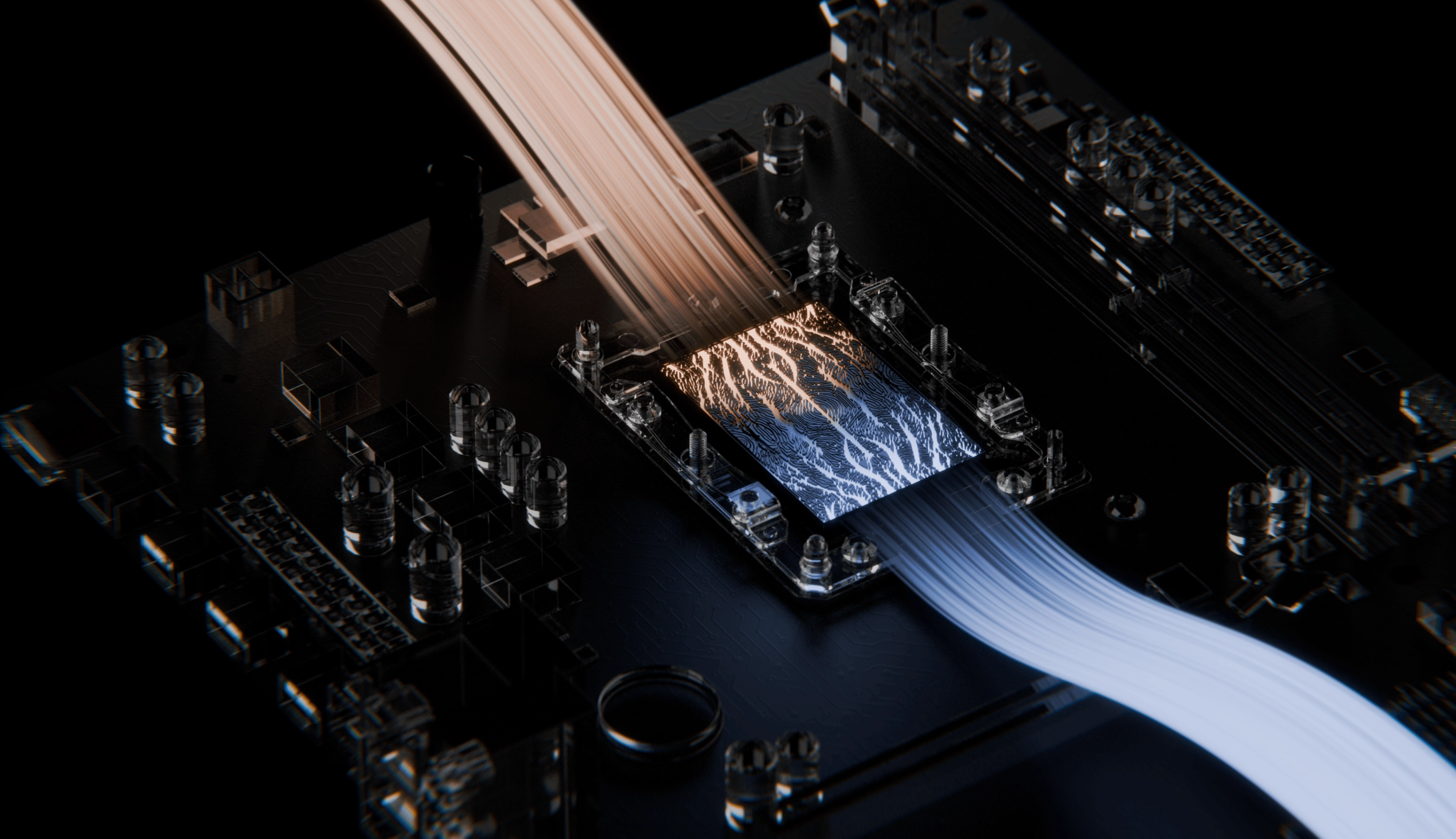

We’re building 10× better chip-cooling to unlock the next 100× better compute

Featured in

Cooling is the ultimate bottleneck for silicon chips that drive AI and cloud computing.

The next 100× increase in compute performance will require 10× better cooling and current data center cooling solutions can´t keep up with the rising heat.

Liquid cooling is the new standard, and we set the standard for designing, building, testing and mass-producing leading-edge liquid cooling for high-power chips in data centers.

High-end chips

are heating up

Cooling

datacenter

globally

water consumed annualy

100B

liters

Cooling datacenter

globally consumes

more electricity than

New York

& London

combined

GPU memory clock2,000Mhz

GPU core voltage1.025V

GPU core load98%

GPU memory clock2,000Mhz

GPU thermal limit100ºc

Heatflux400w/cm2

GPU power1893W

40c+inlet temperature

Introducing CorintisChip cooling redefined

Unlock the next leap in compute performance with Corintis: Targeted microfluidic cooling, tailored for performance and efficiency, to reliably run the most powerful chips at the lowest possible temperatures. Designed with micro-scale precision for large-scale production, to future-proof your data center & HPC applications.

Up to 10× better chip-cooling

Be one step ahead of the heat by using our streamlined platform to design, build, test, and mass-produce the world’s best microfluidic cold plates and co-packaged cooling solutions. Achieve higher TDP with less flow rate and pressure drop in a shorter cycle time. Just like nature, we harness evolution to tailor cooling to the chip, bringing the right amount of liquid to the right location and achieving maximum cooling performance.

Currently in closed Beta

Glacierware

Our world-class design platform

Over 50 in-house experts

Based in Lausanne, Switzerland

Whitepaper

Ask for the Corintis Whitepaper